Aluminium – more sustainable than you think.

The significance of aluminium is steadily increasing, given decisive megatrends such as sustainability, climate targets, decarbonisation, the circular economy and urban mining. As the metal of the future, it is an essential component of a modern, changing society.

Aluminium plays a central role in a world that needs more sustainable materials manufactured with lower emissions – materials that do not burden the environment during use, are recyclable and have a longer service life.

Sustainable aluminium at Schweizer.

The quantity of aluminium procured by Schweizer in 2023 was 5,350 tonnes. A variety of alloys are used for different product groups, including the following:

Recycled aluminium:

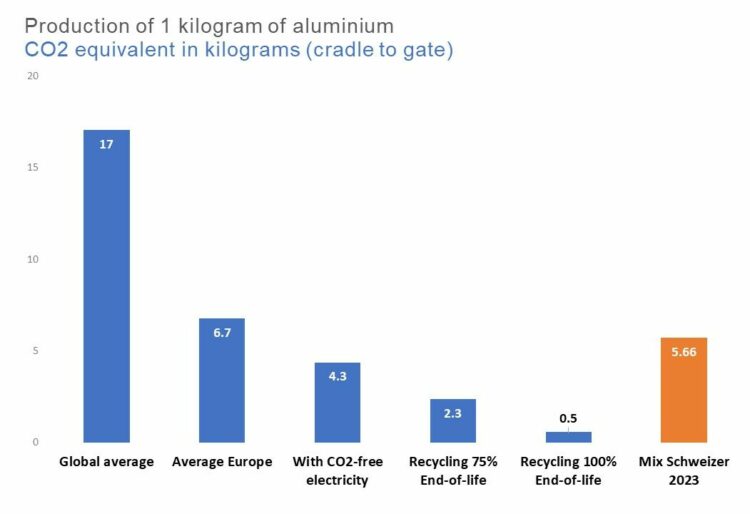

This consists of at least 75% end-of-life aluminium (old scrap). Its footprint of 2.3 kg of CO2 per kg of aluminium is one of the lowest in the world.

Low-emission aluminium:

This material is produced using renewable energies such as water, wind and solar power. The maximum value of its footprint is 4 kg of CO2 per kg of aluminium.

Thanks to long-standing partnerships, we are able to prioritise sustainable materials. This approach means that we are making a significant and verifiable contribution to reducing CO2 emissions. 15% of the volume procured by Schweizer has a CO2 equivalent of 4.0 kg CO2 / kg aluminium or less (including all process steps according to Scope 1, 2, 3).

Our focus.

-

«Swiss premiere for 100% recycled aluminium»

We installed façade elements for the Metro-Campus Zurich made of 100% recycled aluminium, the first project of its kind in Switzerland and only the third completed in Europe. This reduces the CO2 footprint around 40 times when compared to the global average, and without any loss of quality. In specific terms, this saved over 167 tonnes of CO2. This is equivalent to the emissions of around 890,000 kilometres travelled by car or 73 flights from Zurich to New York.

To the press release -

«A metal of the future»

In an expert interview conducted by «Arc Mag» Marc Bremgartner, a member of the Schweizer management board, answers questions about the role of aluminium as an essential building block of a modern, changing society.

To the expert interview (German) -

MSP PV installation system: Transparency regarding CO2 emissions

The Solar.Pro.Tool from Schweizer automatically shows the CO2 emissions caused by the MSP PV mounting system for each respective system configuration. This allows the energy amortisation period for projects to be determined more precisely, providing environmentally conscious investors, architects, EPCs and installers with important information on the CO2 footprint of their construction project.

To the planning software

On the way to a circular economy.

We see ourselves as an enabler of sustainable construction and a modern circular economy in which raw materials are utilised in closed cycles wherever possible. With this in mind, we support developers, architects, planners and specialist partners in reducing their carbon footprint, thus contributing to the energy revolution.